Top Advantages of Thatch Imitation Rattan Machines

In recent years, the demand for sustainable and durable outdoor materials has led to a significant increase in the use of synthetic rattan and thatch. Thatch imitation rattan machines have emerged as crucial tools in this industry, offering numerous benefits for manufacturers and consumers alike. These machines are designed to produce synthetic rattan fibers that mimic the natural look and feel of traditional rattan, making them ideal for crafting furniture, garden décor, and various outdoor products. In this article, we will delve into the top advantages of thatch imitation rattan machines, exploring how they enhance production efficiency, sustainability, and product quality.

1. Improved Production Efficiency

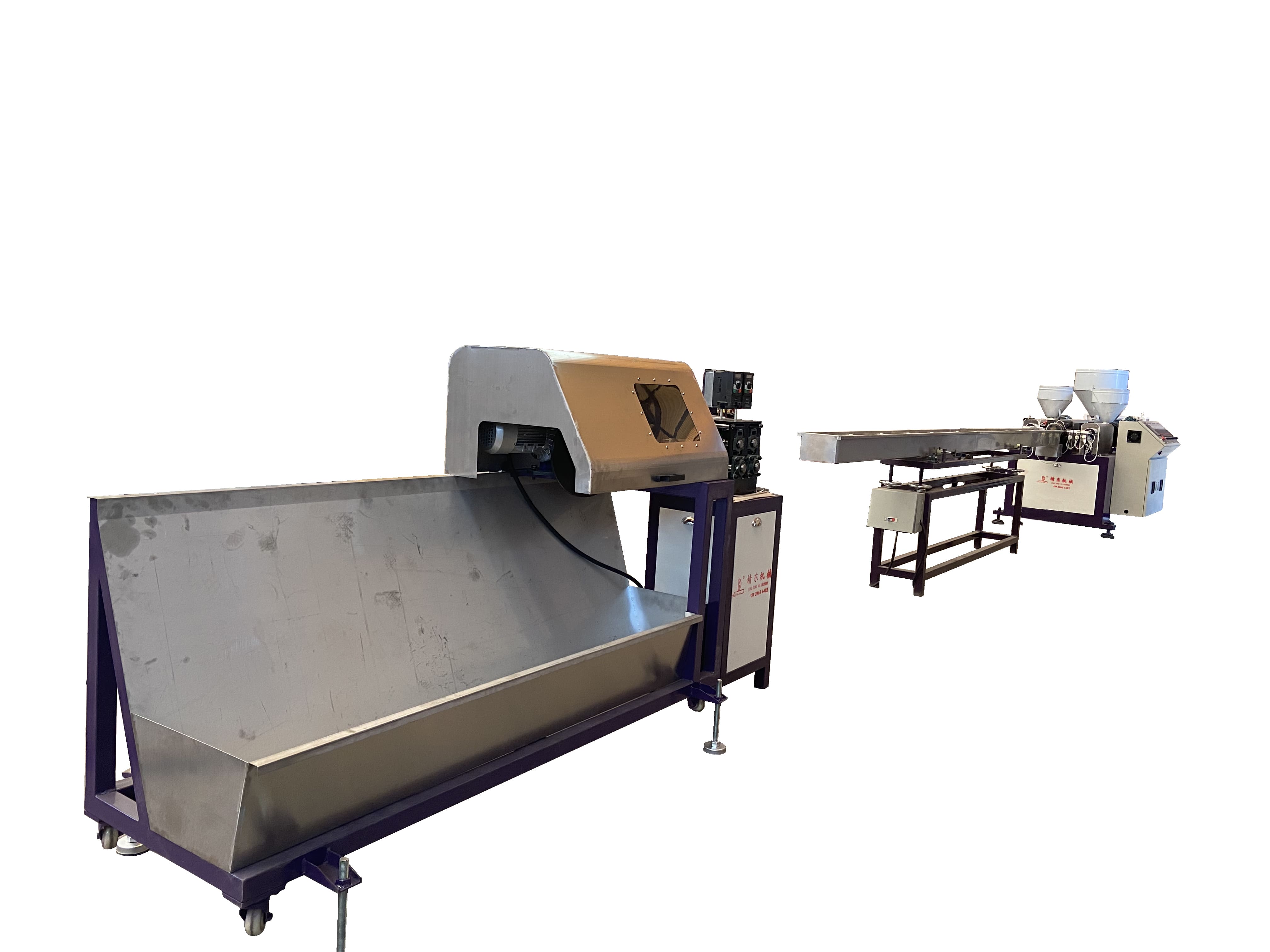

One of the most significant advantages of thatch imitation rattan machines is their ability to improve production efficiency. These machines are equipped with advanced extrusion technology that allows for the continuous production of synthetic rattan strands. This process is highly automated, reducing the need for manual labor and minimizing downtime. As a result, manufacturers can produce large volumes of synthetic rattan with consistent quality, meeting high demand without sacrificing product standards.

Key Features Enhancing Efficiency:

Advanced Extrusion Systems: These systems melt and extrude raw plastic materials into uniform strands, ensuring strength and flexibility.

Automated Processes: From mixing and extrusion to cooling and winding, automated control systems streamline production, maintaining precision and consistency.

High-Speed Production: Machines can operate at high speeds, significantly reducing production time compared to manual methods.

2. Cost Savings and Economic Benefits

Investing in a thatch imitation rattan machine can lead to substantial cost savings for manufacturers. By automating the production process, labor costs are significantly reduced. Additionally, the precise extrusion process minimizes material waste, further lowering production expenses. Energy-efficient features also help reduce utility bills, making these machines a cost-effective choice for long-term operations.

Economic Advantages:

Reduced Labor Costs: Automation minimizes the need for manual intervention, saving on labor expenses.

Energy Efficiency: Modern machines are designed to be energy-efficient, reducing operational costs and environmental impact.

Minimal Waste: Precise extrusion ensures that material usage is optimized, reducing waste and saving resources.

3. Enhanced Sustainability and Eco-Friendliness

Thatch imitation rattan machines contribute to sustainability by using recycled plastics and reducing waste. Synthetic rattan itself is a durable, low-maintenance alternative to traditional rattan, offering a longer lifespan and requiring less frequent replacement. This not only conserves natural resources but also appeals to eco-conscious consumers seeking environmentally responsible products.

Sustainable Practices:

Use of Recycled Materials: Many synthetic rattan products are made from recycled plastics, reducing landfill waste and conserving natural resources.

Longer Product Lifespan: Synthetic rattan lasts longer than natural rattan, reducing the need for frequent replacements and minimizing waste.

Low Maintenance: Synthetic products are resistant to pests and rot, reducing the need for chemical treatments and preserving natural ecosystems.

4. Customization and Versatility

Modern thatch imitation rattan machines offer high customization capabilities, allowing manufacturers to produce synthetic rattan fibers in various colors, textures, and sizes. This flexibility enables businesses to cater to specific customer demands and target niche markets with unique products. Whether it's furniture, garden accessories, or automotive interiors, these machines can adapt to meet diverse application needs.

Customization Options:

Adjustable Settings: Machines allow for adjustments in extrusion speed, temperature, and strand thickness to meet specific product requirements.

Diverse Applications: Synthetic rattan can be used in furniture, garden décor, lighting fixtures, and more, providing opportunities for manufacturers to expand their product lines.

Market Differentiation: By offering unique and customizable products, businesses can differentiate themselves in competitive markets.

5. Aesthetic Appeal and Authenticity

Thatch imitation rattan machines produce fibers that closely mimic the natural appearance of traditional rattan. This aesthetic appeal is crucial for outdoor furniture and décor, as it provides a natural, tropical look without the drawbacks of natural materials. The simulation effect is so excellent that synthetic rattan is increasingly preferred for projects requiring a natural ambiance.

Aesthetic Benefits:

Natural Appearance: Synthetic rattan fibers are designed to replicate the texture and color of natural rattan, offering an authentic look.

Tropical Ambiance: Ideal for creating a tropical or exotic atmosphere in outdoor spaces, synthetic rattan enhances aesthetic appeal without compromising durability.

Color Consistency: Unlike natural materials, synthetic rattan maintains consistent color over time, ensuring a uniform appearance throughout its lifespan.

6. Fire Resistance and Safety

Synthetic thatch and rattan products manufactured using these machines often incorporate fire-resistant materials, enhancing safety in outdoor settings. This is particularly important for public spaces like resorts and hotels, where fire safety is a top priority. The use of fire-retardant ingredients ensures that these products meet stringent safety standards.

Safety Features:

Fire-Retardant Materials: Synthetic thatch and rattan are made with materials that resist ignition and the spread of fire, providing enhanced safety.

Compliance with Standards: Products meet or exceed fire safety standards, such as the B1 fire-retardant standard, ensuring compliance with regulatory requirements.

Peace of Mind: For consumers and businesses, the fire-resistant nature of synthetic products offers peace of mind, especially in high-risk environments.

7. Easy Installation and Maintenance

Synthetic thatch and rattan products are designed to be lightweight and easy to install. Unlike natural materials, they require minimal maintenance, as they are resistant to rot and pests. This makes them ideal for projects where upkeep is a concern, such as in remote or hard-to-reach locations.

Installation and Maintenance Benefits:

Lightweight: Synthetic materials are easier to transport and install compared to heavy natural materials.

Low Maintenance: Products are impervious to pests and rot, reducing the need for frequent repairs or replacements.

Durability: Synthetic thatch and rattan withstand harsh weather conditions, ensuring long-term performance without significant degradation.

Conclusion

Thatch imitation rattan machines have revolutionized the production of synthetic rattan and thatch, offering a range of benefits that enhance efficiency, sustainability, and product quality. By leveraging advanced technology and customization capabilities, manufacturers can meet growing demand for eco-friendly and durable outdoor materials. As consumers increasingly seek sustainable solutions that mimic natural aesthetics without the drawbacks, these machines play a vital role in driving innovation and growth in the industry. Whether for furniture, roofing, or décor, the advantages of thatch imitation rattan machines make them an indispensable tool for businesses looking to stay competitive and environmentally responsible in the modern market.