Synthetic Rattan Composite Extrusion Machine: Transform Outdoor Furniture Production

The outdoor furniture industry is experiencing a substantial transformation, largely driven by advancements in manufacturing technologies. Among these innovations, the synthetic rattan composite extrusion machine stands out as an excellent means of enhancing production efficiency, contributing to the sustainability and durability of outdoor furniture.

In this article, we will delve into how this technology is revolutionizing the industry, its numerous benefits, and why it is essential for manufacturers aiming to remain competitive in a rapidly evolving market.

All About Synthetic Rattan Composite Extrusion Machines

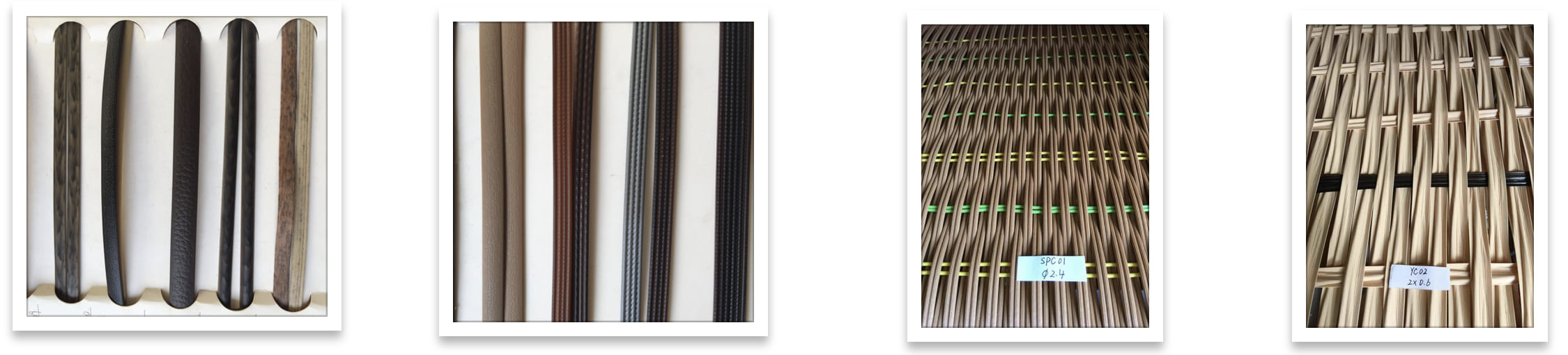

Synthetic rattan composite extrusion machines are specialized pieces of equipment designed to produce high-quality synthetic rattan materials used in outdoor furniture. These machines employ advanced extrusion technology to create durable, weather-resistant materials that closely mimic the appearance of natural rattan while offering superior performance.

Key features of these machines include:

- High Efficiency: Capable of producing large volumes of synthetic rattan quickly, these machines significantly reduce lead times for manufacturers, allowing them to meet growing consumer demand without sacrificing quality.

- Customization: The machines allow for the production of various shapes and sizes tailored to specific furniture designs. This flexibility enables manufacturers to innovate and create unique products that stand out in the market.

- Sustainability: Utilizing recyclable materials in the production process contributes to eco-friendly manufacturing practices, aligning with the increasing consumer preference for sustainable products.

- User-Friendly Operation: Many modern machines come equipped with intuitive interfaces and automated controls that simplify operations and reduce training time for staff

Furniture Rattan Extrusion

Benefits of Using Synthetic Rattan Composite Extrusion Machines

Investing in a synthetic rattan composite extrusion machine can yield numerous advantages for furniture manufacturers:

Cost-Effectiveness

The efficiency of these machines reduces labor costs and material waste, leading to higher profit margins. Manufacturers can produce more with less, optimizing their operational budgets.

Durability

Products made from synthetic rattan are resistant to UV rays, moisture, and temperature fluctuations. This durability ensures longevity, reducing replacement costs and enhancing customer satisfaction.

Aesthetic Appeal

The ability to mimic natural materials allows manufacturers to offer visually appealing products without compromising on quality. This aesthetic versatility can attract a broader range of consumers.

Market Demand

With increasing consumer preference for sustainable and durable outdoor furniture, utilizing synthetic rattan can help manufacturers effectively meet market demands while promoting eco-friendly practices.

Real-world Applications

Numerous furniture manufacturers are already reaping the benefits of synthetic rattan composite extrusion machines. For instance, companies specializing in outdoor furniture have reported increased production rates and improved product quality after integrating these machines into their operations.

One notable example involves a manufacturer that transitioned from traditional materials to synthetic rattan. This shift not only improved their product line but also attracted environmentally conscious consumers, significantly boosting sales. By offering a wider range of products that appeal to modern aesthetics and sustainability concerns, they have positioned themselves as leaders in the industry.

Optimizing Production with Advanced Technology

Incorporating a synthetic rattan composite extrusion machine into your production line can streamline operations significantly. Here's how:

- Automated Processes: Automation reduces human error and ensures consistent product quality. Manufacturers can rely on precise control over material properties during production.

- Real-Time Monitoring: Advanced machines come equipped with monitoring systems that allow for immediate adjustments during production, enhancing efficiency and minimizing downtime.

- Training and Support: Many suppliers offer comprehensive training programs for operators, ensuring that your team can maximize the machine's capabilities. Ongoing technical support can also help troubleshoot issues quickly.

- Integration with Existing Systems: These machines can often be integrated seamlessly into existing production lines, allowing manufacturers to upgrade their capabilities without overhauling their entire operation.

Recommended Product: Plastics Rattan Combine Extruder

For manufacturers looking to enhance their production capabilities, the Plastics Rattan Combine Extruder is an excellent choice. This advanced machine allows for the creation of diverse products, such as imitation rattan furniture and decorative items.

Key features include:

- Touch Screen Control: Simplifies operation with clear parameters for quick adjustments, enabling operators to respond swiftly to changing production needs.

- Automatic Control Technology: Enhances efficiency through automated processes that minimize manual intervention while maximizing output consistency.

- Versatile Production Options: Capable of producing various types of synthetic rattan, including tri-color options that add visual interest and variety to product lines.

- The extruder's design includes easy-to-seal components and quick-connect electric boxes that facilitate the addition of auxiliary equipment without requiring specialized electricians. This user-friendly approach ensures that even less experienced employees can operate it effectively.

By integrating the Plastics Rattan Combine Extruder into your manufacturing line, you can significantly boost productivity while maintaining high standards of quality and sustainability.

Conclusion

The synthetic rattan composite extrusion machine represents a pivotal advancement in the outdoor furniture manufacturing sector. By adopting this technology, manufacturers can enhance their production capabilities while meeting consumer demands for quality and sustainability. As the industry continues to evolve, those who invest in innovative solutions like these will undoubtedly lead the market.

To learn more about how Jingdong Machinery can provide tailored solutions for your manufacturing needs, contact us today. Our expertise in custom rattan extruder solutions positions us as your ideal partner in achieving operational excellence and driving growth in your business!