PVC Soft Pipe Extruders: Key Features and Applications in Various Industries

PVC soft pipe extruders are advanced machines designed to produce a wide range of soft PVC products, including flexible tubing and profiles. These extruders play a crucial role in various industries due to their versatility, efficiency, and ability to produce high-quality products. This article will delve into the key features of PVC soft pipe extruders and explore their applications across different sectors.

Introduction to PVC Soft Pipe Extruders

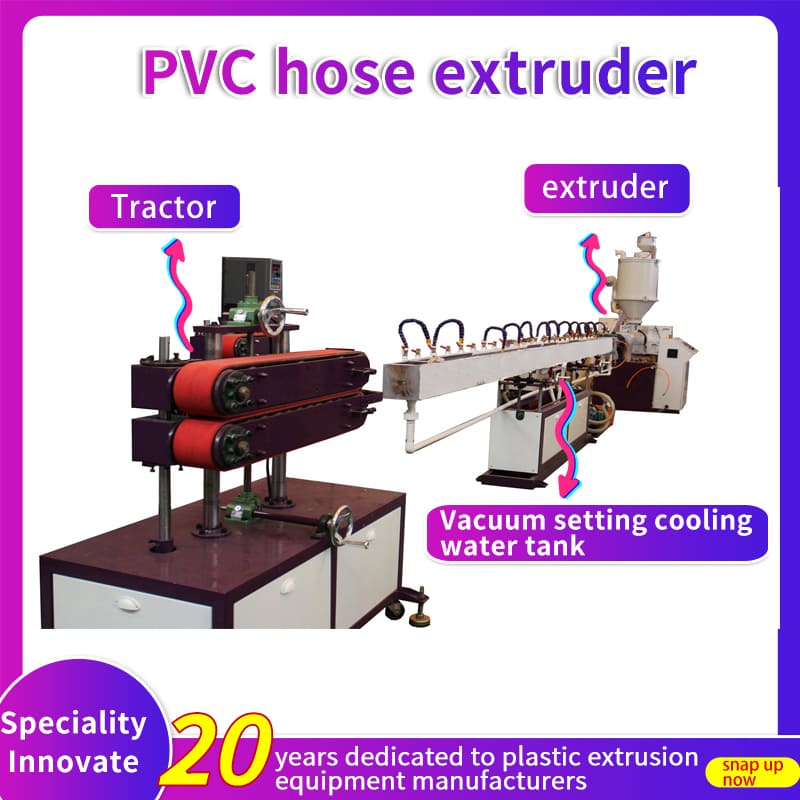

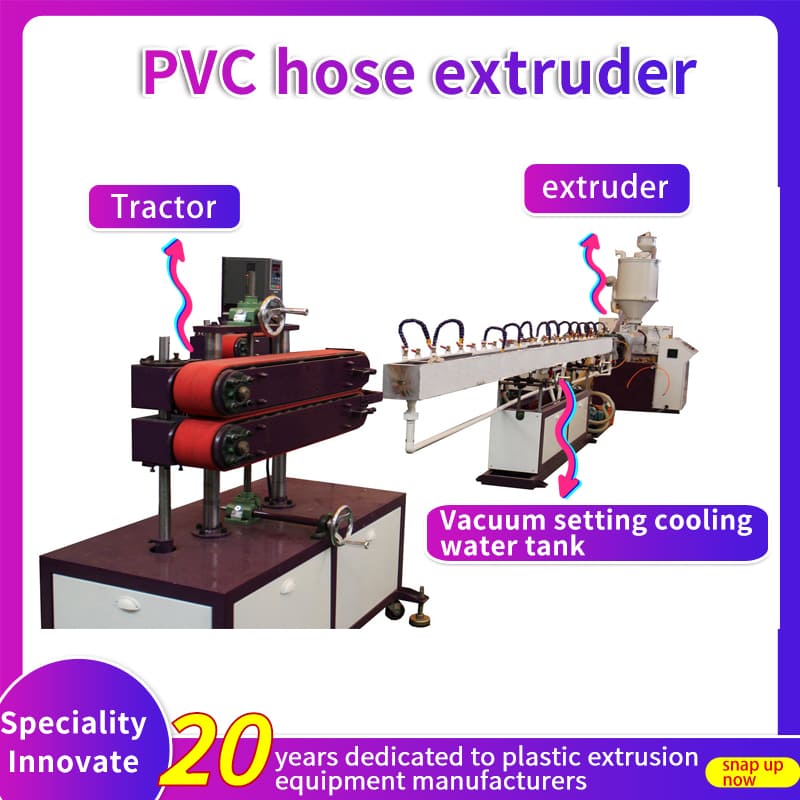

PVC soft pipe extruders are specialized machines that utilize thermoplastic extrusion technology to process PVC compounds into flexible and durable products. The extrusion process involves heating and melting the PVC material, which is then pushed through a die to achieve the desired shape. These machines are equipped with advanced technology that allows for precise control over temperature, pressure, and material flow, ensuring consistent product quality.

Key Features of PVC Soft Pipe Extruders

Versatility and Customization: PVC soft pipe extruders are highly versatile, capable of producing a variety of shapes and sizes. They can be customized with different dies and settings to meet specific product requirements, making them suitable for diverse applications.

Efficiency and Productivity: These extruders are designed to optimize production efficiency. They incorporate energy-efficient components and streamlined processes to maximize output while minimizing waste and energy consumption.

Durability and Reliability: Constructed from high-quality materials, PVC soft pipe extruders are built to withstand continuous operation. Proper maintenance ensures they remain reliable workhorses in manufacturing facilities.

Advanced Technology: The use of advanced technology in these extruders allows for precise control over every aspect of the extrusion process. This includes temperature regulation, pressure management, and material flow, ensuring consistent product quality.

Applications in Various Industries

PVC soft pipe extruders find applications in several industries due to the versatility and durability of PVC products.

Construction and Infrastructure

In the construction industry, PVC pipes and tubing are widely used for plumbing, drainage, and electrical conduit systems. Their durability, resistance to corrosion, and cost-effectiveness make them ideal for infrastructure projects. PVC extruders can produce customized profiles for architectural designs, such as window frames and door frames, which offer excellent insulation properties.

Medical and Pharmaceutical

The medical sector utilizes PVC extrusions for products like medical tubing, IV bags, and dialysis kits. PVC's ease of sterilization and chemical resistance meet the stringent hygiene requirements of medical applications. The flexibility of PVC allows for customized medical equipment, further enhancing its importance in healthcare.

Automotive

In the automotive industry, PVC extruders are used to produce components such as insulation for electrical wiring and interior trims. PVC's durability, flexibility, and weather resistance make it a preferred material for parts exposed to harsh conditions.

Electrical and Plumbing

PVC extruders are instrumental in producing PVC conduit pipes and insulation for wiring in electrical installations. These products are valued for their non-conductivity, fire resistance, and durability. In plumbing, PVC pipes are popular due to their resistance to corrosion, ease of installation, and lightweight nature.

Food, Beverage, and Chemical Transfer

Flexible PVC tubing is ideal for transferring food, beverages, fuels, and chemicals due to its resistance to corrosion and contamination. This tubing is widely used in industries where hygiene and safety are paramount.

Benefits of Using PVC Soft Pipe Extruders

Cost-Effectiveness: PVC extruders offer a cost-effective solution for manufacturing PVC products. The extrusion process is generally more economical than other plastic-forming methods, and the use of automated systems reduces labor costs.

Environmental Sustainability: These machines facilitate the use of recycled PVC, contributing to waste reduction and promoting sustainable manufacturing practices.

Innovation and Customization: PVC extruders allow for adjustments to the extrusion process, enabling the development of new and innovative PVC products. This fosters industry growth and advancement by providing customized solutions for diverse applications.

Future Developments and Innovations

As technology continues to evolve, PVC soft pipe extruders are expected to incorporate even more advanced features. Innovations in energy efficiency, automation, and material processing will further enhance the productivity and sustainability of these machines. Additionally, the development of new PVC compounds with improved properties will expand the range of applications for PVC products.

Conclusion

PVC soft pipe extruders are vital components in modern manufacturing, offering unparalleled efficiency, versatility, and durability. Their applications span multiple industries, from construction and medical to automotive and electrical. As the demand for flexible and durable PVC products continues to grow, the role of PVC soft pipe extruders in meeting this demand will remain crucial. With ongoing innovations in technology and materials, these extruders will continue to play a pivotal role in shaping the future of PVC production.

In summary, PVC soft pipe extruders are not just machines; they are key enablers of innovation and sustainability in the plastic industry. Their ability to produce high-quality, customized PVC products efficiently and cost-effectively makes them indispensable in various sectors. As industries evolve and new applications emerge, the importance of PVC soft pipe extruders will only continue to grow.