PVC Plastic Flexible Tube Extruder: Revolutionizing Pipe Production

In the dynamic world of plastic manufacturing, the PVC plastic flexible tube extruder stands out as a game-changing innovation. This advanced machinery has transformed the production of flexible PVC pipes, offering unparalleled efficiency and quality. Whether you're in the construction, automotive, or medical industry, understanding the capabilities of a PVC soft pipe extruder is crucial for staying competitive in today's market.

The Power of PVC Tube Extrusion Machines

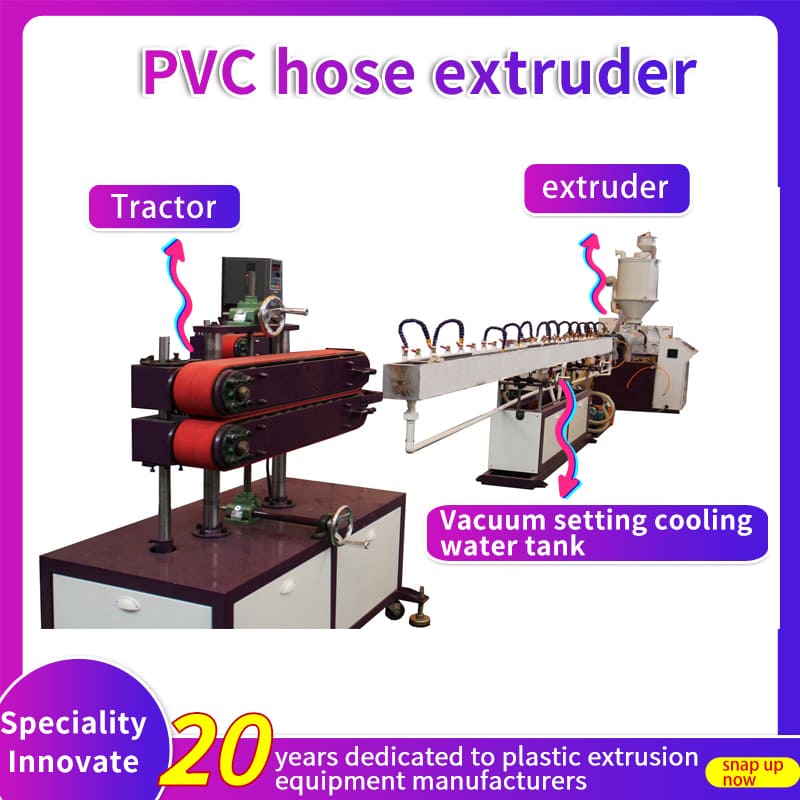

At the heart of flexible PVC pipe production lies the PVC tube extrusion machine. These sophisticated systems are designed to melt, shape, and cool PVC material into a wide range of pipe sizes and configurations. The process begins with raw PVC pellets or powder being fed into the extruder's hopper. As the material moves through the barrel, it's heated and compressed by a rotating screw, transforming into a homogeneous melt.

The molten PVC then passes through a die, which gives the pipe its shape. Immediately after exiting the die, the pipe enters a cooling tank where it solidifies. This precise control over temperature and pressure throughout the extrusion process ensures consistent pipe quality and dimensional accuracy.

Advantages of PVC Soft Pipe Extruders

Investing in a high-quality PVC hose extruder offers numerous benefits:

Increased Production Efficiency: Modern PVC extruders can produce pipes at remarkable speeds, significantly boosting output.

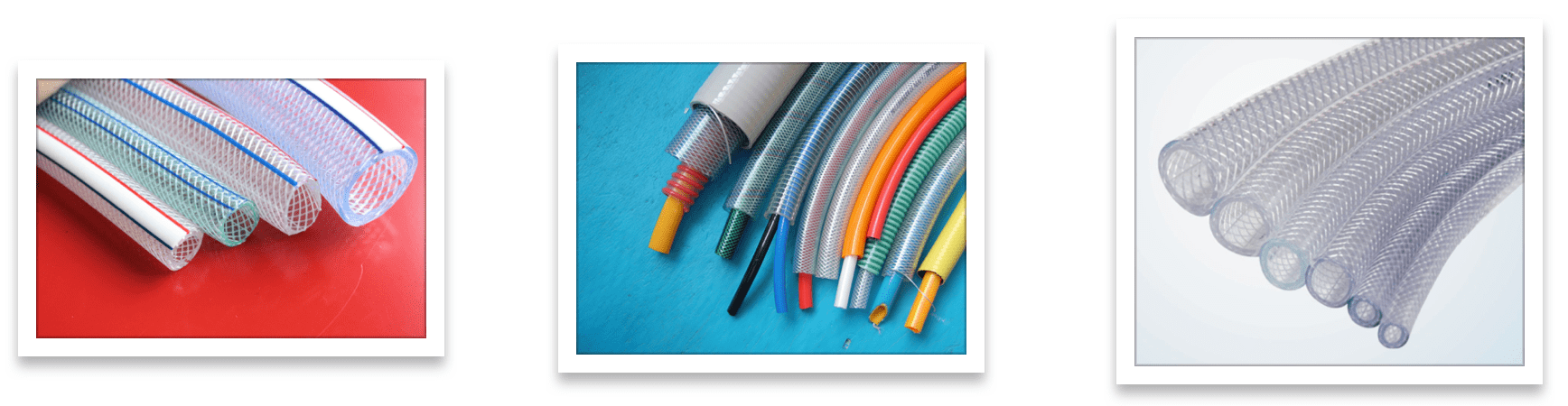

Versatility: These machines can handle a wide range of PVC formulations, allowing for the production of pipes with varying flexibility, durability, and chemical resistance.

Cost-Effectiveness: By optimizing material usage and reducing waste, PVC extruders help manufacturers lower production costs.

Customization: Advanced extruders offer the flexibility to produce pipes with specific diameters, wall thicknesses, and properties to meet diverse industry needs.

Choosing the Right PVC Plastic Flexible Tube Extruder

When selecting a PVC plastic flexible tube extruder, consider the following factors:

Production Capacity: Ensure the extruder's output aligns with your production goals.

Screw Design: Look for extruders with optimized screw configurations for efficient melting and mixing of PVC compounds.

Temperature Control: Precise temperature management throughout the extrusion process is crucial for product quality.

Cooling System: An effective cooling system is essential for maintaining the desired pipe dimensions and properties.

Automation Features: Advanced control systems can enhance production consistency and reduce operator dependency.

Innovations in PVC Soft Pipe Extruder Technology

The latest PVC soft pipe extruders incorporate cutting-edge features to enhance performance:

Energy Efficiency: New designs focus on reducing power consumption without compromising output.

Quick Change-over: Modular components allow for faster product change-overs, minimizing downtime.

Intelligent Control Systems: Advanced software enables real-time monitoring and adjustment of extrusion parameters.

Enhanced Material Compatibility: Modern extruders can process a broader range of PVC formulations, including those with high filler content.

Applications of PVC Flexible Tubes

The versatility of PVC tube extrusion machines allows for the production of pipes used in various industries:

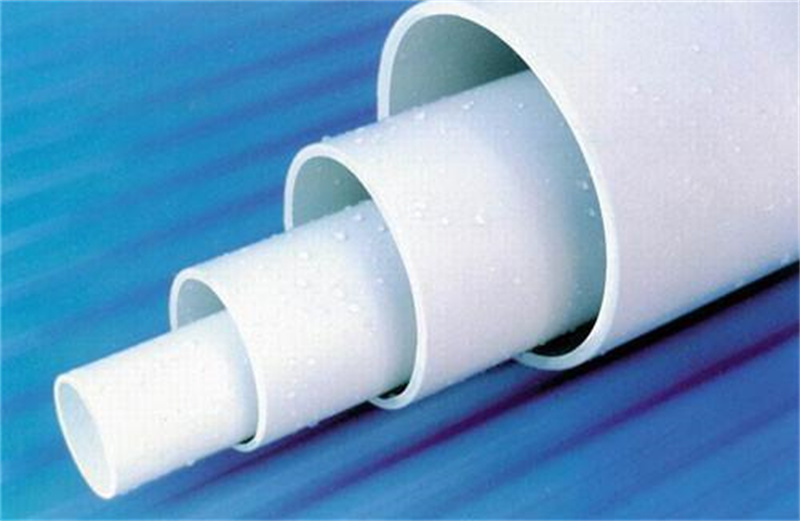

Construction: Flexible PVC pipes are widely used in plumbing, electrical conduits, and irrigation systems.

Automotive: PVC hoses find applications in fuel lines, windshield washer systems, and air conditioning units.

Medical: Flexible PVC tubing is essential in medical devices, such as IV lines and catheters.

Agriculture: PVC pipes are used extensively in drip irrigation and sprinkler systems.

PVC soft pipe extruder applications

Maximizing ROI with PVC Hose Extruders

To get the most out of your PVC hose extruder investment:

Regular Maintenance: Implement a rigorous maintenance schedule to ensure optimal performance and longevity.

Operator Training: Invest in comprehensive training programs to maximize machine efficiency and product quality.

Quality Control: Implement strict quality control measures to maintain consistent pipe properties.

Continuous Improvement: Stay informed about the latest extrusion technologies and upgrade your equipment when necessary.

Conclusion: Embracing the Future of PVC Pipe Production

The PVC plastic flexible tube extruder represents the pinnacle of pipe production technology. By investing in these advanced systems, manufacturers can significantly enhance their production capabilities, product quality, and market competitiveness. As the demand for flexible PVC pipes continues to grow across various industries, staying ahead with cutting-edge extrusion technology is not just an option—it's a necessity.

For those looking to elevate their PVC pipe production, exploring high-quality PVC soft pipe extruders is the first step toward manufacturing excellence. With the right equipment and expertise, you can meet the evolving demands of the market and position your business for long-term success. Discover how advanced extrusion technology from Jingdong can transform your production line and drive your business forward!