The Ultimate Guide to Plastic Pelletizing Machines

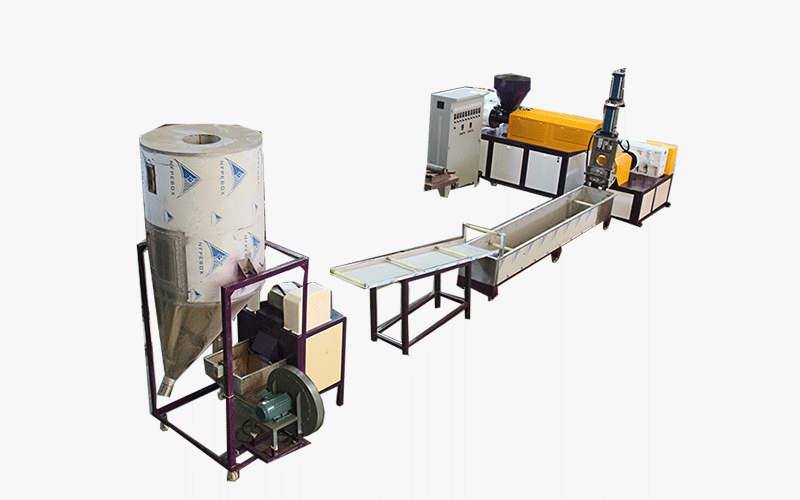

Plastic pelletizing machines play a critical role in the plastic recycling industry. They transform plastic waste into uniform pellets that can be reused in manufacturing processes, thereby contributing to a sustainable and circular economy. This guide will delve into the intricacies of plastic pelletizing equipment, its importance, how it works, and what to look for when investing in plastic pelletizing equipment.

What is a Plastic Pelletizing Machine?

The plastic pelletizing machine, also known as the plastic pelletizer or plastic pelletizing equipment, is a device used to convert plastic waste into small, uniform pellets. These pellets, also known as plastic granules, can be reused to manufacture new plastic products. The process involves melting down plastic materials, extruding them through a die, and then cutting the extruded strands into pellets. This not only helps reduce plastic waste but also ensures that recycled material can be effectively reintegrated into the production cycle, maintaining a high quality of end products.

Why Plastic Pelletizing Machines Are Essential

Plastic plastic pelletizing equipment is vital for several reasons:

- Environmental Benefits: By recycling plastic waste, pelletizing machines help reduce the amount of plastic pollution and conserve resources. The pellets produced can replace virgin plastic, thus reducing the demand for new plastic production and the associated environmental footprint.

- Economic Advantages: Pellets produced can be sold or reused, reducing the cost of raw materials. This makes it economically viable for manufacturers to incorporate recycled materials into their production processes, leading to significant cost savings.

- Quality Control: The pelletizing process ensures uniformity in size and composition, which is crucial for consistent product quality. Uniform pellets ensure smooth processing in subsequent manufacturing stages, resulting in high-quality end products.

How Does a Plastic Pelletizer Work?

The plastic pelletizing process involves several key steps:

- Feeding: Plastic waste is fed into the machine through a hopper. This can include a variety of plastic types, from bottles to packaging materials, which are sorted and pre-processed to remove any contaminants.

- Melting: The plastic is heated and melted in the extruder. The extruder uses high temperatures and mechanical shear to melt the plastic uniformly, preparing it for extrusion.

- Extruding: The molten plastic is pushed through a die to form strands. The design of the die determines the shape and size of the pellets.

- Cooling: The extruded strands are cooled, usually by water or air. This step solidifies the plastic strands, making them ready for cutting.

- Cutting: The cooled strands are cut into uniform pellets by a rotating knife. The size of the pellets can be adjusted based on the specific requirements of the end-use application.

Types of Plastic Pelletizing Equipment

There are several types of plastic pelletizing equipment available, each suited for different applications:

- Single-Screw Pelletizers: Ideal for simple recycling tasks with consistent material types. These are commonly used for basic recycling operations where the plastic feedstock does not vary significantly.

- Twin-Screw Pelletizers: Suitable for more complex recycling processes, offering better mixing and compounding capabilities. They are ideal for handling a mix of different plastic types and additives, providing superior homogenization.

- Underwater Pelletizers: These are used for high-output applications where the pellets are immediately cooled by water. This method is efficient for large-scale operations and helps in achieving a smooth and glossy pellet surface.

- Air-Cooled Pelletizers: Suitable for materials that do not require water cooling and are sensitive to moisture. They are preferred in applications where water cooling might affect the quality of the pellets, such as in the recycling of hygroscopic plastics.

Key Features to Consider

When selecting a plastic pelletizer, consider the following features:

- Output Capacity: Choose a machine that matches your production needs. High-output machines are essential for large-scale recycling operations to ensure efficiency and productivity.

- Material Compatibility: Ensure the machine can handle the types of plastic you intend to recycle. Some machines are designed to process specific plastics better than others, so it's crucial to match the machine's capabilities with your material types.

- Automation Level: Higher automation can lead to greater efficiency and consistency. Automated machines reduce the need for manual intervention, minimizing errors and labor costs.

- Energy Efficiency: Opt for machines that offer energy-saving features to reduce operational costs. Energy-efficient machines not only lower electricity bills but also contribute to environmental sustainability.

- Maintenance Requirements: Consider the ease of maintenance and availability of spare parts. Machines that are easy to maintain and have readily available parts reduce downtime and extend the machine's lifespan.

Advantages of Using High-performance Plastic Pelletizing Machines

Investing in high-performance plastic pelletizing equipment brings several benefits:

- Enhanced Productivity: Advanced machines offer higher throughput, reducing production time. This allows manufacturers to meet high demand and increase their production capabilities.

- Improved Quality: Consistent pellet size and quality lead to better end-product performance. High-quality pellets ensure smooth processing in manufacturing, resulting in superior products.

- Cost Savings: Efficient machines reduce energy consumption and operational costs. Lower energy usage and reduced waste generation lead to significant cost savings over time.

- Flexibility: Modern machines can handle a variety of plastic types and recycling processes. This versatility makes it easier for manufacturers to adapt to changing market demands and material availability.

Jingdong's Expertise in Plastic Pelletizing Solutions

At Jingdong, we specialize in providing high-performance plastic pelletizing machines tailored to meet diverse industrial needs. Our machines are designed with state-of-the-art technology to ensure superior performance, durability, and efficiency. We offer comprehensive solutions that include machine installation, maintenance, and support, ensuring that our clients achieve optimal results from their investments.

Explore our range of plastic pelletizers at Jingdong and transform your plastic recycling process today.

Conclusion

Plastic pelletizing machines are indispensable in the plastic recycling industry, providing environmental, economic, and quality benefits. By understanding the different types of machines and their features, you can make an informed decision that meets your production needs. With Jingdong's comprehensive range of high-performance plastic pelletizing equipment, you can enhance your recycling process and contribute to a sustainable future. Contact us today to learn more about our solutions and how they can transform your business.