Maximize Recycling Output With Plastic Pelletizer System

In today's drive toward sustainability, recycling plays a crucial role in reducing waste and conserving resources. A plastic pelletizer system stands at the forefront of this movement, offering a solution that transforms plastic waste into reusable pellets ready for manufacturing. Businesses in industries such as packaging, automotive, and construction can significantly benefit from these systems. This article delves into how a well-optimized plastic pelletizer system can maximize recycling output, enhance efficiency, and contribute to a circular economy.

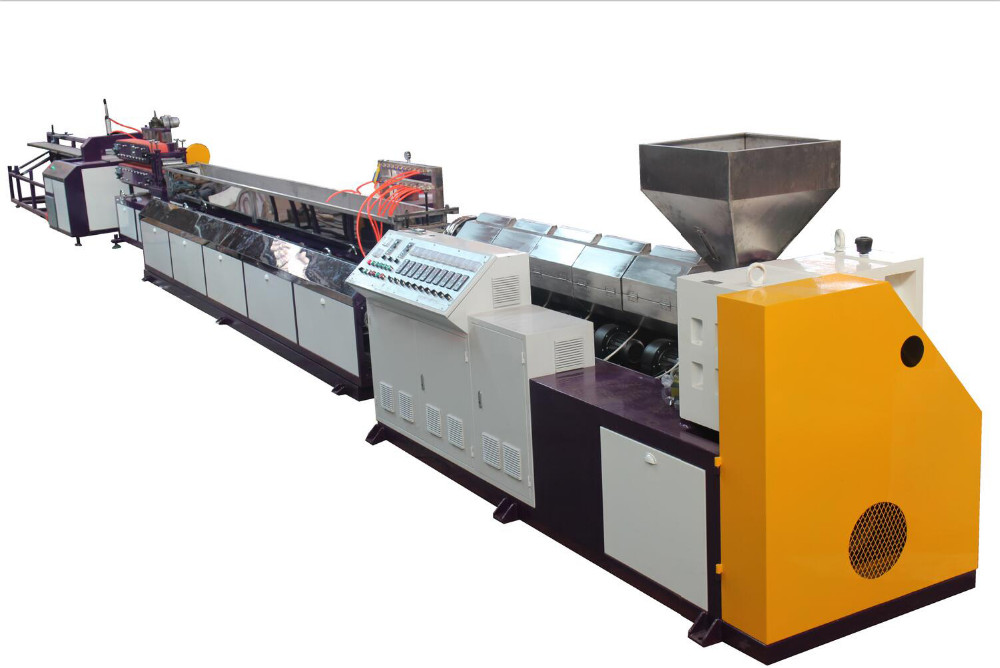

Understanding the Plastic Pelletizer System

A plastic pelletizer system is an advanced recycling solution designed to process plastic waste into uniform, high-quality pellets. These pellets serve as raw material for manufacturing new products, reducing the need for virgin plastic. The system typically includes shredding, extrusion, and pelletizing equipment that works seamlessly to convert post-industrial and post-consumer plastic waste into valuable resources.

The system is suitable for processing various plastics, including polyethylene (PE), polypropylene (PP), polystyrene (PS), and more. By integrating a plastic pelletizer system, businesses can streamline recycling processes, reduce costs, and achieve greater environmental compliance.

Plastic Recycling Pelletizing Machine Line

Key Benefits of a Plastic Pelletizer System

1. Enhanced Recycling Efficiency

Traditional recycling methods often result in inconsistent output and higher wastage. A plastic pelletizer system ensures precise processing, producing uniform pellets with minimal material loss. This efficiency translates to higher output, enabling companies to meet the increasing demand for recycled materials.

2. Cost Savings

Investing in a plastic pelletizer system allows businesses to cut costs in two key areas:

- Waste management: Reducing the volume of waste sent to landfills lowers disposal costs.

- Raw material procurement: Reusing plastic pellets decreases the dependency on costly virgin plastic.

3. Customizable Solutions

Modern plastic pelletizer systems come with customizable configurations, allowing businesses to tailor the system to their specific waste types and processing requirements. This flexibility ensures optimal performance and maximum ROI.

4. Environmental Benefits

By incorporating a plastic pelletizer system into operations, companies can significantly reduce their carbon footprint. Recycling plastic reduces energy consumption and greenhouse gas emissions associated with virgin plastic production. It also minimizes plastic pollution, contributing to a healthier environment.

5. Compliance With Regulations

Stringent regulations on waste management and recycling are compelling businesses to adopt sustainable practices. A plastic pelletizer system helps companies comply with environmental laws and enhance their reputation as eco-friendly organizations.

Features of an Efficient Plastic Pelletizer System

When selecting a plastic pelletizer system, it's important to consider features that ensure efficient and reliable operation:

- Energy efficiency: Advanced systems consume less energy, reducing operational costs.

- High throughput: Look for systems capable of processing large volumes of plastic waste quickly and effectively.

- Durable construction: Materials like stainless steel and wear-resistant components enhance the system's longevity.

- Automated controls: Automation reduces labor requirements and minimizes errors, improving overall efficiency.

- Versatility: A system that can handle multiple plastic types and contaminants is ideal for businesses with diverse recycling needs.

Industries Benefiting From Plastic Pelletizer Systems

Manufacturing

Manufacturers can integrate a plastic pelletizer system into their production line to recycle scrap material and improve sustainability. The recycled pellets can be reused to create packaging materials, automotive parts, and construction products.

Waste Management Companies

Waste management firms leverage these systems to process collected plastic waste, converting it into marketable recycled pellets for resale.

Retail and Packaging

Retailers and packaging companies can install plastic pelletizer systems to handle returned or damaged goods, repurposing them into valuable raw materials.

Plastic Recycling/Pelletizing Machine

Best Practices for Maximizing Output With a Plastic Pelletizer System

Regular Maintenance

Consistent maintenance ensures the system operates at peak efficiency. Cleaning, lubrication, and timely replacement of wear parts can prevent downtime and prolong equipment life.

Employee Training

Properly trained operators can enhance the system's productivity by minimizing errors and identifying issues early. Investing in training ensures smooth operations and reduces the learning curve.

Quality Control

Implementing strict quality checks on the input material and output pellets ensures a superior product. Avoiding contaminants in the input material can prevent equipment damage and maintain output consistency.

Upgrading Technology

Technological advancements continually improve pelletizer performance. Upgrading outdated systems or components can boost capacity and reduce energy consumption, offering long-term benefits.

Jingdong: Your Trusted Partner for Plastic Pelletizer Systems

As a leading manufacturer and supplier of plastic pelletizer systems in China, Jingdong offers state-of-the-art solutions tailored to meet your recycling needs. Our systems are designed to deliver maximum efficiency, durability, and output, enabling businesses to stay competitive in a rapidly evolving market.

At Jingdong, we pride ourselves on delivering:

- Cutting-edge technology

- Customizable designs for diverse applications

- Comprehensive support services, including installation and maintenance

Whether you're in manufacturing, waste management, or packaging, our plastic pelletizer systems can help you achieve your sustainability goals while maximizing ROI.

Conclusion

A plastic pelletizer system is an essential investment for businesses aiming to boost recycling output and embrace sustainability. By offering efficiency, cost savings, and environmental benefits, these systems not only support waste reduction but also enhance profitability. Partnering with Jingdong ensures you receive reliable, high-performance solutions designed to meet the unique demands of your industry.

Explore our range of plastic pelletizer systems today to take your recycling efforts to the next level. Contact us to learn more about how Jingdong can help you succeed in building a sustainable future.