Heavy-Duty Synthetic Rattan Extruders: Boosting Manufacturing Output

Heavy-duty synthetic rattan extruders are revolutionizing the manufacturing industry, offering unparalleled efficiency and productivity. These advanced machines, also known as plastic rattan extrusion equipment, are designed to handle even the most demanding production requirements, ensuring consistent quality and exceptional output. In this article, we will explore the key features and benefits of heavy-duty synthetic rattan extruders, highlighting their importance in modern manufacturing processes.

The Importance of Heavy-Duty Synthetic Rattan Extruders

Heavy-duty synthetic rattan extruders play a crucial role in the manufacturing of a wide range of products, from furniture to automotive parts. These machines are capable of processing various types of synthetic materials, including polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC), with exceptional precision and speed.

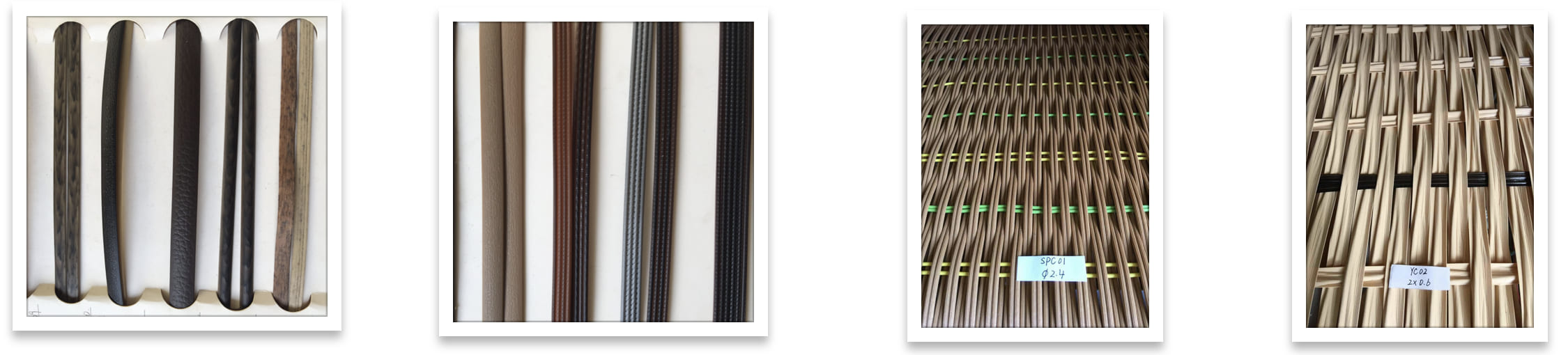

One of the primary advantages of heavy-duty synthetic rattan extruders is their ability to produce high-quality, consistent products. The advanced technology used in these machines ensures that each piece meets strict quality standards, reducing waste and improving overall efficiency. These extruders are used to produce plastic rattan strips of various shapes and colors, such as round rattan, flat rattan, embossed rattan, seagrass rattan, etc., which are widely used in indoor and outdoor furniture like tables, chairs, sofas and various woven crafts.

Key Features of Heavy-Duty Synthetic Rattan Extruders

Heavy-duty synthetic rattan extruders are designed with a range of features that contribute to their effectiveness and reliability. Some of the most notable features include:

High-Capacity Feeding System

These extruders are equipped with a high-capacity feeding system that can handle large volumes of raw materials, ensuring continuous production and minimizing downtime. The plastic rattan machine has undergone a number of technological innovations, featuring high speed, high extrusion volume, low melt temperature, good material plasticizing effect, and a dual-combination color matching feeding system.

Precise Temperature Control

Accurate temperature control is crucial in the extrusion process, as it ensures the proper melting and shaping of the synthetic materials. Heavy-duty synthetic rattan extruders feature advanced temperature control systems that maintain consistent temperatures throughout the production cycle. The ideal extrusion temperature range for virgin PLA pellets is between 180 °C and 190 °C.

Durable Construction

The machines are built with high-quality materials and robust construction, making them capable of withstanding heavy use and harsh environments. This durability translates to reduced maintenance costs and extended machine life. The extruder accuracy can be tested to define the optimal extrusion process parameters, ensuring consistent performance.

Benefits of Using Heavy-Duty Synthetic Rattan Extruders

The use of heavy-duty synthetic rattan extruders offers numerous benefits to manufacturers, including:

Increased Production Capacity

These machines are designed to handle large volumes of raw materials, allowing manufacturers to increase their production capacity and meet growing demands.

Improved Efficiency: With their advanced features and precise control systems, heavy-duty synthetic rattan extruders can produce consistent, high-quality products more efficiently, reducing waste and increasing profitability.

Enhanced Flexibility

These extruders can process a variety of synthetic materials, enabling manufacturers to adapt to changing market demands and diversify their product offerings. Some models of plastic rattan extruders can arbitrarily change the surface color of the rattan, making it applicable to the production of various shapes of high-grade plastic rattan strips and sheets.

Cost Savings

By reducing waste, minimizing downtime, and increasing productivity, heavy-duty synthetic rattan extruders can help manufacturers save on production costs and improve their bottom line.

Recommended Product: Plastics Rattan Combine Extruder

One of the leading products in the heavy-duty synthetic rattan extruder market is the Plastics Rattan Combine Extruder from Jingdong. This advanced machine is designed to handle even the most demanding production requirements, offering exceptional efficiency and reliability.

Some of the key features of the Plastics Rattan Combine Extruder include:

- * High-capacity feeding system for continuous production

- * Precise temperature control for consistent product quality

- * Durable construction for long-lasting performance

- * Flexible design for processing various synthetic materials

Conclusion

Heavy-duty synthetic rattan extruders are essential tools for modern manufacturers looking to boost their productivity and efficiency. With their advanced features, precise control systems, and durable construction, these machines offer numerous benefits, including increased production capacity, improved efficiency, enhanced flexibility, and cost savings. By investing in a high-quality, heavy-duty synthetic rattan extruder like the Plastics Rattan Combine Extruder from Jingdong, manufacturers can stay ahead of the competition and meet the growing demands of the market.