Efficient Filament Production with Dust-Proof Strip Extruders

In the realm of filament production, maintaining cleanliness and efficiency is paramount. Dust and debris can significantly impact the quality of the final product, leading to defects and inconsistencies. To address these challenges, dust-proof strip extruders have emerged as a crucial innovation in the industry. This article delves into the importance of dust-proof strip extruders in efficient filament production, their design and functionality, and how they contribute to optimizing the manufacturing process.

Introduction to Filament Production

Filament production is a critical process in various industries, including 3D printing, textiles, and plastics manufacturing. The quality of the filament directly affects the performance and durability of the end product. For instance, in 3D printing, high-quality filaments are essential for achieving precise prints with minimal defects. However, the production environment can be prone to dust and other contaminants, which can compromise filament quality.

Challenges in Traditional Filament Production

Traditional filament production methods often face several challenges:

Dust and Contamination: Dust particles can easily embed into the filament during production, leading to inconsistent quality and potential defects in the final product. This is particularly problematic in applications where precision is key, such as in aerospace and medical devices.

Efficiency and Cost: Traditional methods may require additional steps to clean or filter out contaminants, increasing production time and costs. This can make the process less competitive in a market where efficiency and cost-effectiveness are highly valued.

Environmental Factors: Environmental conditions like humidity and temperature can also affect the quality of the filament. For example, moisture can cause filament to degrade or become brittle, further complicating the production process.

The Role of Dust-Proof Strip Extruders

Dust-proof strip extruders are designed to address these challenges by providing a clean and controlled environment for filament production. Here are some key features and benefits of these extruders:

Design and Functionality

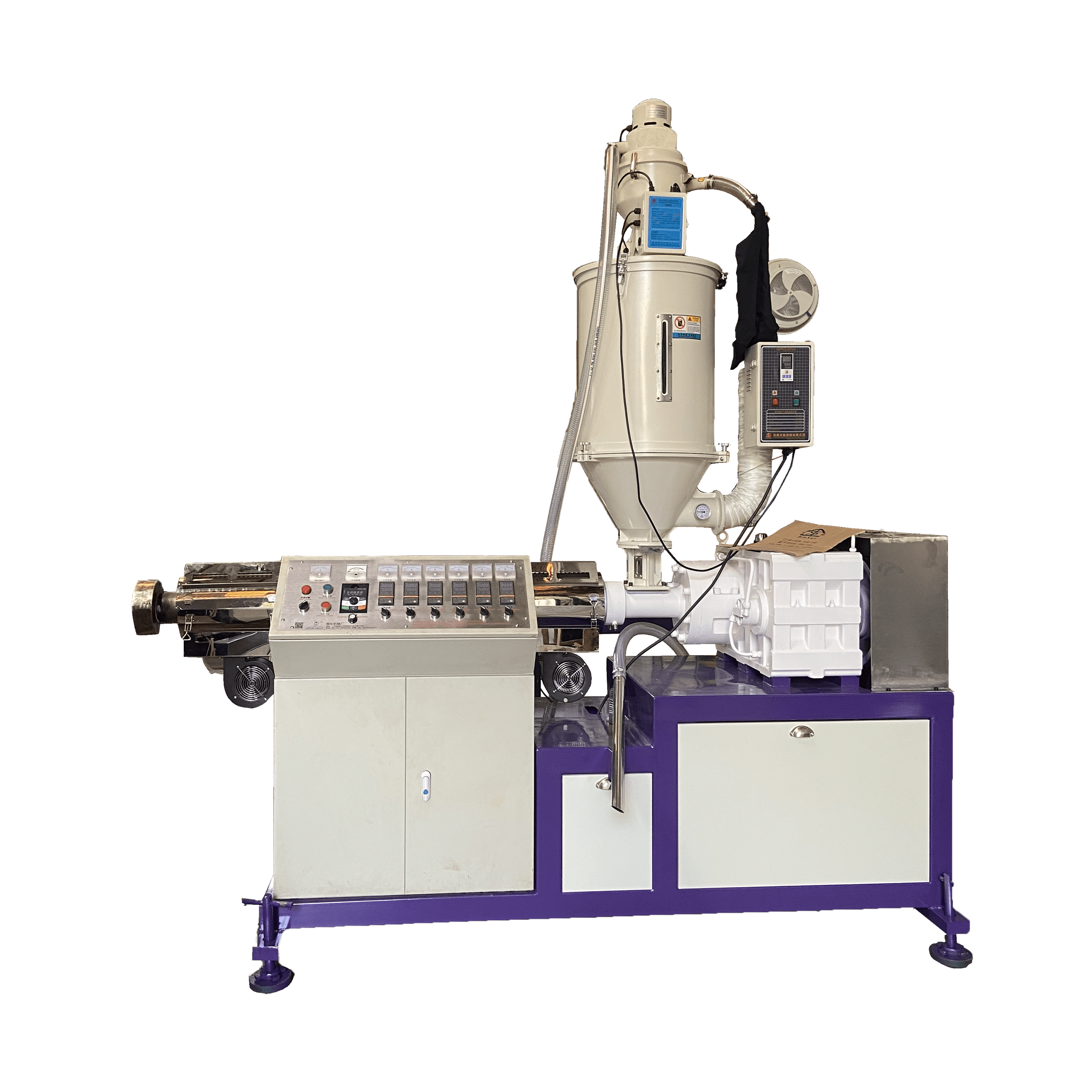

Enclosed System: Dust-proof strip extruders operate within an enclosed system, which prevents dust and other contaminants from entering the production area. This ensures that the filament remains clean throughout the extrusion process.

Advanced Materials: These extruders often use high-quality materials that are resistant to wear and tear, ensuring durability and longevity. The use of advanced materials also helps in maintaining a consistent temperature and pressure, crucial for producing uniform filaments.

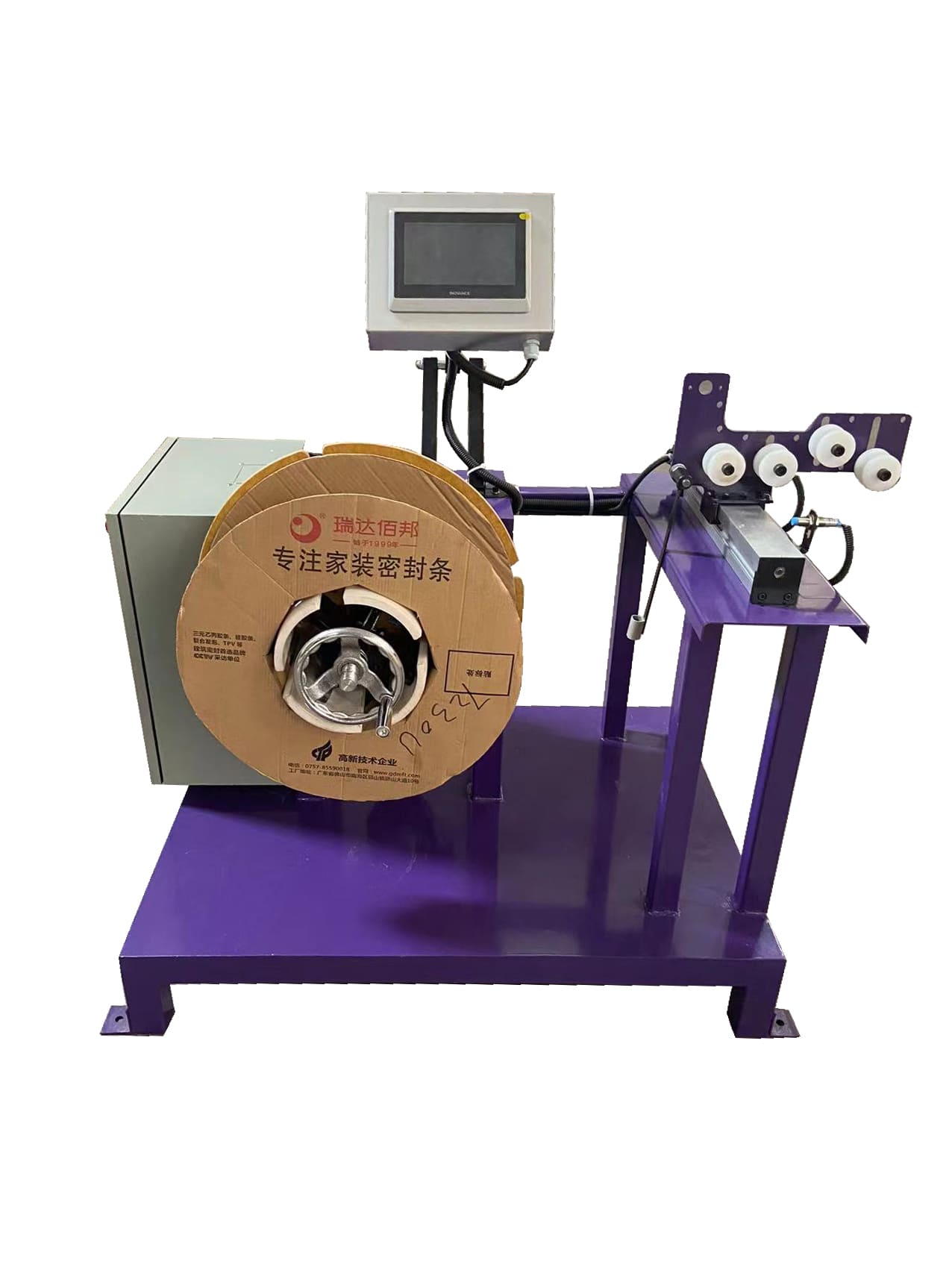

Automation: Many dust-proof strip extruders come equipped with automated features such as online weighing, meter counting, and winding. These features not only reduce labor costs but also enhance precision by minimizing human error.

Benefits in Filament Production

Improved Quality: By minimizing dust and contaminants, dust-proof strip extruders help produce filaments with consistent quality. This is particularly important in applications where high precision is required.

Increased Efficiency: The automated processes and enclosed systems reduce the need for additional cleaning steps, thereby speeding up production and lowering operational costs.

Environmental Adaptability: These extruders can be designed to operate effectively under various environmental conditions, making them suitable for use in different manufacturing settings.

Applications of Dust-Proof Strip Extruders

Dust-proof strip extruders have a wide range of applications across various industries:

3D Printing: In 3D printing, high-quality filaments are essential for achieving precise prints. Dust-proof strip extruders help ensure that the filaments used are free from contaminants, leading to better print quality and reliability.

Textiles: In textile manufacturing, filaments are used to produce fabrics and other materials. Clean filaments are crucial for maintaining fabric quality and preventing defects.

Plastics Manufacturing: Dust-proof strip extruders are also used in the production of plastic strips and profiles, where cleanliness is vital for ensuring the durability and aesthetic appeal of the final products.

Case Studies and Examples

Several companies have successfully integrated dust-proof strip extruders into their production lines, achieving significant improvements in efficiency and product quality. For instance, Jingdong Plastics Machinery offers advanced dust-proof strip extruders that have been adopted by various industries for their reliability and performance.

Future Developments and Trends

As technology continues to evolve, we can expect dust-proof strip extruders to become even more sophisticated. Future developments may include:

Advanced Automation: Further automation of the production process, including AI-driven monitoring systems to detect and correct any inconsistencies in real-time.

Sustainable Materials: The use of eco-friendly materials in the construction of dust-proof strip extruders, aligning with global efforts to reduce environmental impact.

Integration with Emerging Technologies: Integration with emerging technologies like 3D printing and nanotechnology to produce filaments with unique properties.

Conclusion

Dust-proof strip extruders represent a significant advancement in filament production, offering a solution to long-standing challenges related to cleanliness and efficiency. By providing a controlled environment for extrusion, these machines ensure that filaments are produced with consistent quality, reducing defects and improving overall manufacturing efficiency. As industries continue to evolve and demand higher standards of quality, dust-proof strip extruders will play an increasingly important role in meeting these needs.

In summary, the integration of dust-proof strip extruders into filament production processes is a strategic move towards achieving higher efficiency, quality, and sustainability. Whether in 3D printing, textiles, or plastics manufacturing, these extruders are poised to revolutionize the way filaments are produced, setting new benchmarks for the industry.