Stay Connected:

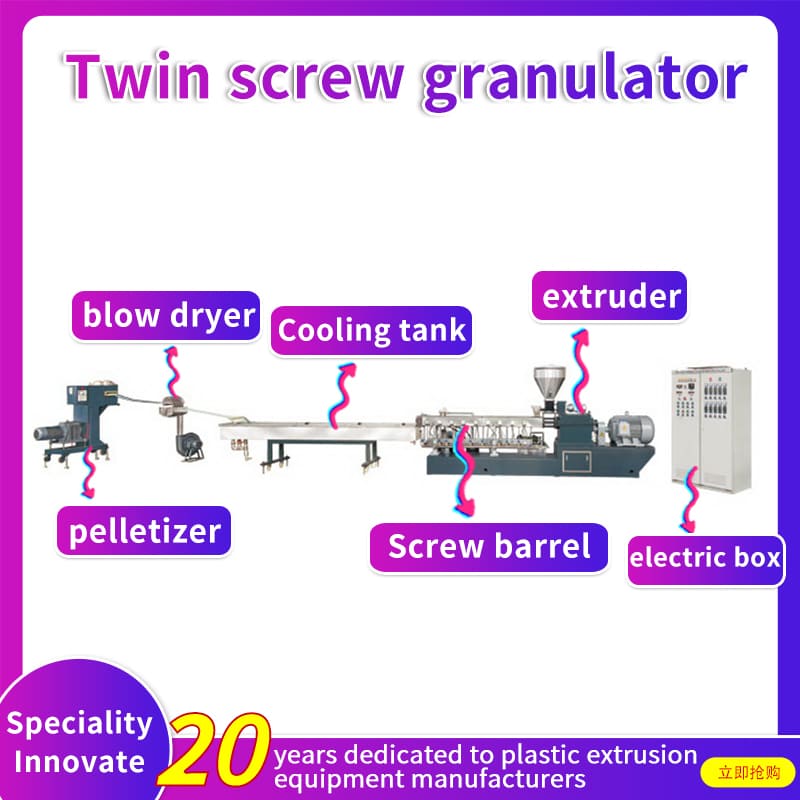

Twin Screw Extruder Pellet Granular Machine

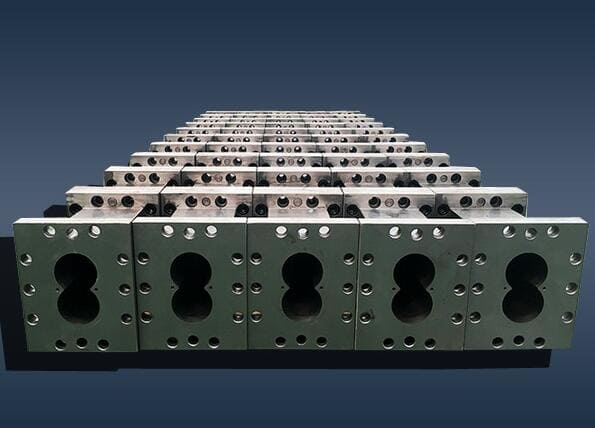

1. The modular thread is fast, and different combinations can be adjusted according to different materials to adapt to different material granulation production.

2. High screw speed and high output.

3. Good shear and mixing effects, widely suitable for various plastic material granulation production.

2. High screw speed and high output.

3. Good shear and mixing effects, widely suitable for various plastic material granulation production.

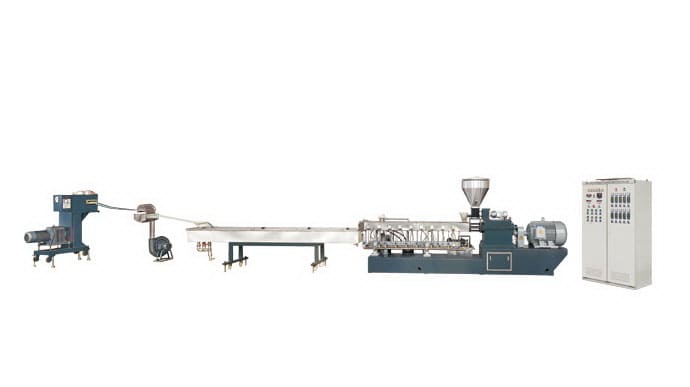

Syntropy parallel screw extruder: it is used for every king of plastics compounding. The extruder provides the advantages of well dispersion and plasticizing, large capacity and low energy consuming. The involute gears is used to smooth operation, lower noise and elongate working life.

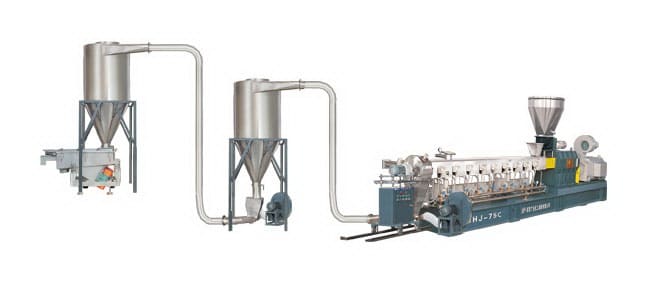

Water bath cutting unit: extruder → mold → water cooling bath → air-drying → cutting unit → storage.

Water ring cutting unit: extruder → water ring cutting mold → dehydrate unit → vibrating screen → storage.

Air-cooling cutting unit: extruder → air-cooling cutting mold → air cooling tower.

Water bath cutting unit: extruder → mold → water cooling bath → air-drying → cutting unit → storage.

Water ring cutting unit: extruder → water ring cutting mold → dehydrate unit → vibrating screen → storage.

Air-cooling cutting unit: extruder → air-cooling cutting mold → air cooling tower.

| Model | screw diam(mm) |

L/D | screw speed(r/min) |

motor power(kW) |

output(㎏/h) |

| SHJ-20 | 21.7 | 28~40 | 600 | 3/4 | 3~15 |

| SHJ-35 | 35.5 | 28~56 | 500 | 11/15 | 20~70 |

| SHJ-50 | 50.5 | 28~56 | 500 | 45/55/75 | 80~150 |

| SHJ-52B | 51.4 | 28~56 | 400/500/600/800 | 45/55/75 | 120~280 |

| SHJ-65 | 62.4 | 28~56 | 500/600 | 55/75/90 | 150~300 |

| SHJ-65B | 62.4 | 28~56 | 400/500/600/800 | 90/110 | 200~500 |

| SHJ-75 | 71 | 28~56 | 500/600 | 90/110/132 | 300~550 |

| SHJ-75B | 71 | 28~56 | 400/500/600/800 | 110/132/180 | 300~700 |

| SHJ-95 | 93 | 28~56 | 400/500 | 250/315 | 600 |

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.