Stay Connected:

Thatch imitation rattan machine

1. Diversity of products can be produced: furniture imitation rattan machine, thatch imitation rattan machine, iron core rattan imitation machine, foaming rattan imitation machine, handicraft imitation rattan machine

2. The equipment is more advanced, with touch screen control, automatic control technology, imitation rattan double-station winding machine (automatic roll change), imitation rattan cutting machine (automatic fixed-length cutting)

3.Patented product - with easy-to-seal design

4.Touch screen control, operating parameters clear, operator quick, and equipment operation fast

5. quickly connect the small electric box, subsequently added auxiliary equipment, such as tractor, brush machine, press machine, cutting machine and other equipment to provide power in this electric box, avoid requiring professional electrician to assemble the line, ordinary (employees can operate it themselves)

6.(Special profit products: quickly install and dismantle the drive chain device, when replacing the press wheel, no need to remove the chain, no release the motor screws, can quickly replace, women can also operate

7.Patented products: tri-colour rattan machine molds

2. The equipment is more advanced, with touch screen control, automatic control technology, imitation rattan double-station winding machine (automatic roll change), imitation rattan cutting machine (automatic fixed-length cutting)

3.Patented product - with easy-to-seal design

4.Touch screen control, operating parameters clear, operator quick, and equipment operation fast

5. quickly connect the small electric box, subsequently added auxiliary equipment, such as tractor, brush machine, press machine, cutting machine and other equipment to provide power in this electric box, avoid requiring professional electrician to assemble the line, ordinary (employees can operate it themselves)

6.(Special profit products: quickly install and dismantle the drive chain device, when replacing the press wheel, no need to remove the chain, no release the motor screws, can quickly replace, women can also operate

7.Patented products: tri-colour rattan machine molds

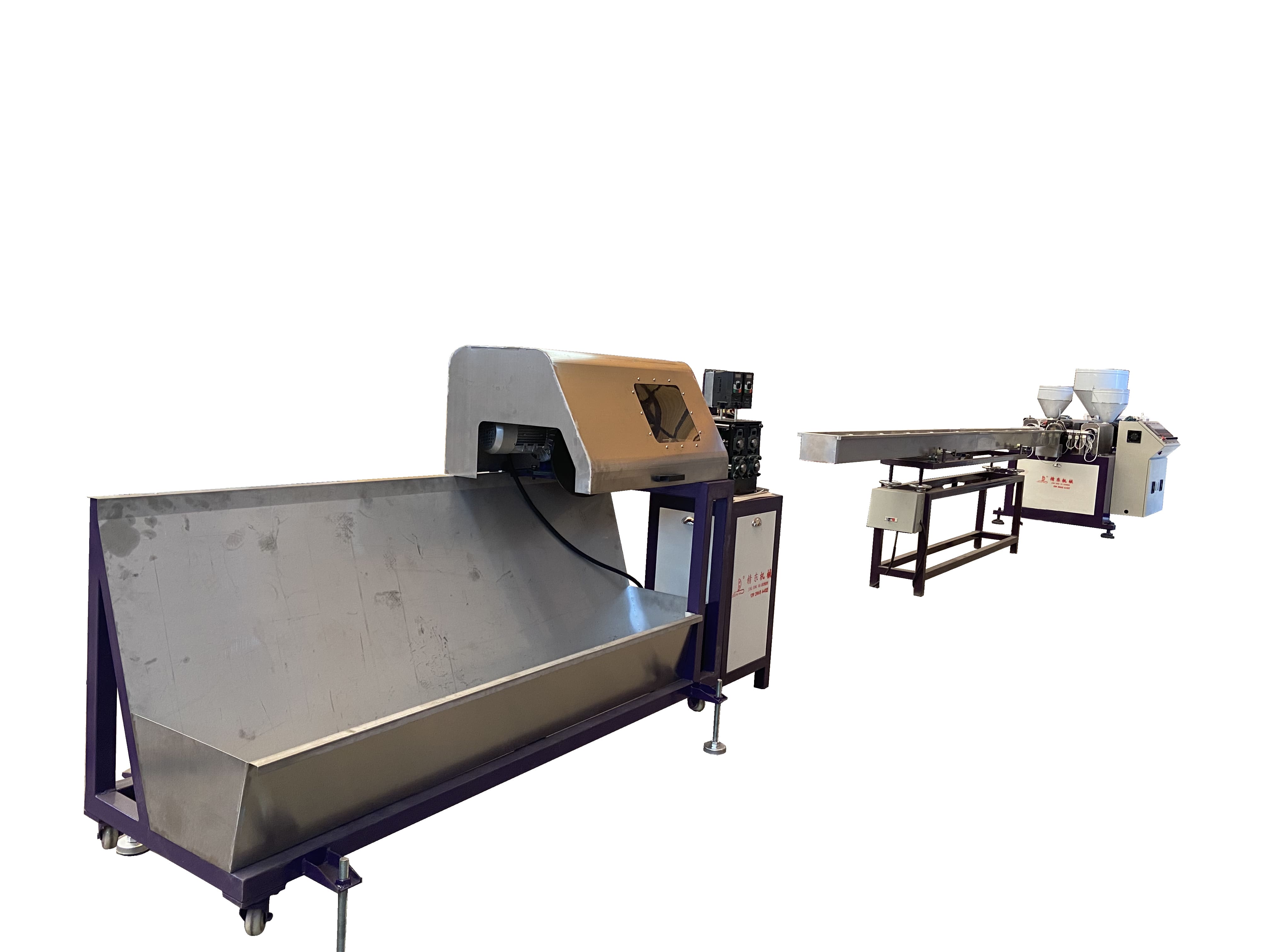

Artificial plastic rattan extruding line

Plastic rattan extruding line has many models. They can produce many kind of plastic rattan, used for furniture and decorating articles etc.

Plastic rattan extruding line:extruder + mould → cooling bath → drawing unit → take-up unit

Iron reinforced rattan extruding line: iron wire rack → wire releasing rack → tensing rack →extruder + mold → cooling bath → drawing unit → take-up unit

| Model | Screw diam. | L/D | Motor power | Heating zone | Cooling bath(m) | Drawing power | Specification |

| Artificial rattan extruder |

45 mm | 28/1 | 5.5 kW | 5 | 4 |

1.5 kW 0.75 kW |

1 mm – 9 mm |

| 50 mm | 27/1 | 7.5 kW | 5 | 5 |

1.5 kW 0.75 kW |

1 mm – 9 mm | |

| 55 mm | 28/1 | 11 kW | 5 | 6 |

1.5 kW 0.75 kW |

1 mm – 9 mm | |

| plastics rattan combine extruder |

55 mm 30 mm * 2 |

28/1 22/1 * 2 |

15 kW 2.2 kW * 2 |

11 | 6 | 1.5 kW 0.75 kW |

1 mm – 18 mm |

| 65 mm 35 mm * 2 |

28/1 25/1 * 2 |

18.5 kW 3 kW * 2 |

11 | 6 | 1.5 kW 0.75 kW |

1 mm – 20 mm | |

| Plastics rattan separated extruder |

55 mm 30 mm * 2 |

28/1 22/1 * 2 |

18.5 kW 3 kW * 2 |

11 | 6 | 1.5 kW 0.75 kW |

1 mm – 20 mm |

| 65 mm 35 mm * 2 |

28/1 25/1 * 2 |

22 kW 4 kW * 2 |

11 | 6 | 1.5 kW 0.75 kW |

1 mm – 20 mm | |

| Iron core rattan extruder |

50 mm | 27/1 | 7.5 kW | 5 | 6 | 1.5 kW 0.75 kW |

1 mm – 9 mm |

| Raw Material:PE output::300 - 1800 kg/day Monochromatic Mechanical Floor Value:12000 mm * 3000 mm * 3000 mm Area for single-color extruding line: ( L12000 mm * W3000 mm * H 3000 mm ) Integrated mechanical floor area value:13000 mm * 3500 mm * 3000 mm Area for combine extruding line: L13000mm *W 3500 mm * H 3000 mm Split mechanical floor area value:13000 mm * 6500 mm * 3000 mm area for separated extruding line: L13000mm *W 6500 mm * H 3000 mm |

|||||||

Application:

Sample:

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.