Glass shower door sealing strip extruder

2.Cheap materials are used inside the product, and good materials are used outside, which greatly reduces the cost.

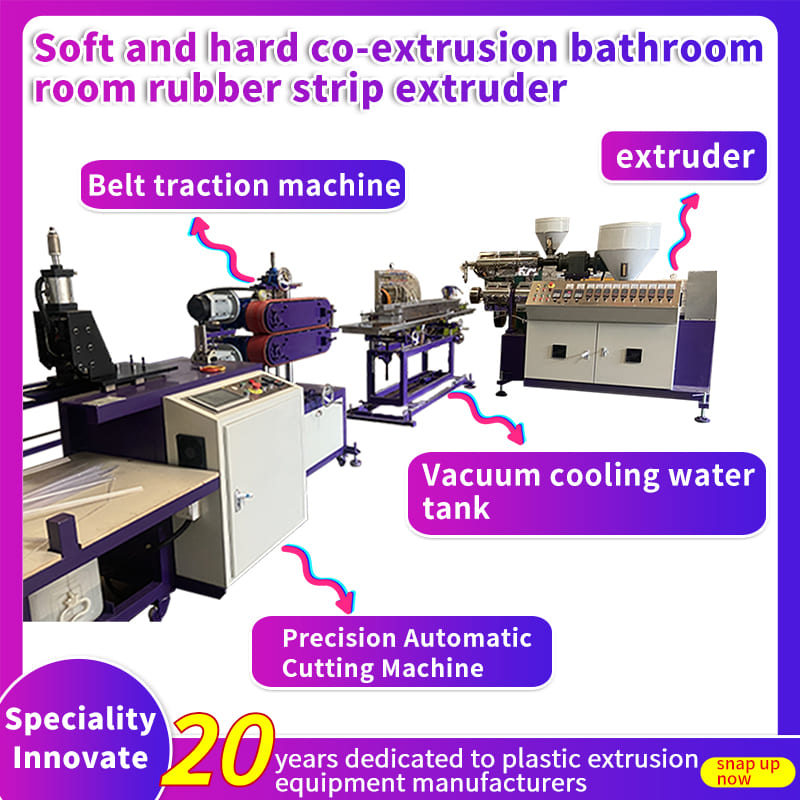

Compose: (2~3) extruders + co-extruding mold → vacuum sizing cooling bath → drawing unit → cutting unit → discharge rack.

The useful raw materials for the line are: PVC, PE, PP, PS, ABS, PC and EVA, etc. 2 or 3 kind of plastics can be selected for co-extrusion.

The line is used to produce flexible/rigid in one sealing strip for bathroom, windscreen wiper, wire trunk, collapsing tag etc.Glass door sealing strip extruder machine,Soft-coated

Adhesive strip extruder machine

| Model | Screw diam.(㎜) |

L/D |

Motor power(kW) |

Output(㎏/h) |

| SJ45/SJ35/(SJ35) | 45/35/(35) | 25:1~28:1 | 11/4/(4) | 25~35 |

| SJ50/SJ45/(SJ45) | 50/45/(45) | 25:1~28:1 | 15/7.5/(7.5) | 35~45 |

| SJ55/SJ45/(SJ45) | 55/45(45) | 25:1~28:1 | 15/7.5/(7.5) | 40~50 |

Application:

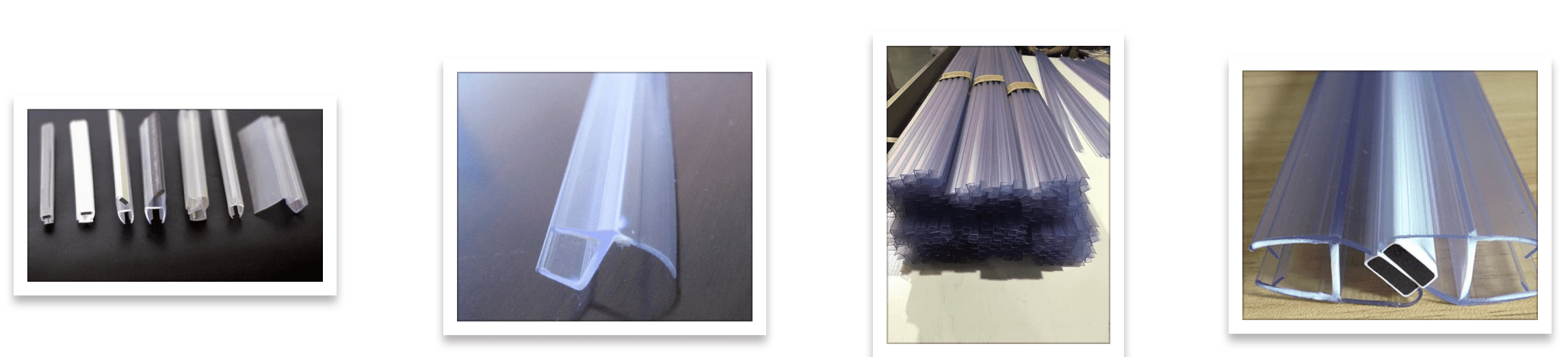

Sealing strip is used for sealing and joining something, providing reduce vibration, block out water and dust, isolate noise and heat, and fix objects together etc. Flexible-rigid in one sealing strip is widely used for bath room ( with magnetic bar ), wiper blade, trunking, water-block-out bar and collapsible TAG etc.

Sample:

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.